The Scientific Necessity of Cleanliness Control in Contact Angle Measurement — A Critical Analysis of Ignoring the Influence of Medium and Surface Detection Phenomena

Introduction: The Underestimated Source of Error

Contact angle measurement is one of the standard methods for assessing the wettability of material surfaces, widely used in fields such as materials science, chemical engineering, surface science, and biomedical applications. It helps researchers understand how liquids interact with solid surfaces, providing crucial references for material design and applications. However, despite the widespread application and significant success of contact angle measurement technology, many experimental results suffer from deviations and errors, particularly in the areas of liquid purity and solid cleanliness. According to numerous experiments, over 90% of measurement errors stem from the neglect of water quality and solid cleanliness, a phenomenon that is prevalent in both academic and industrial fields. Specifically, research has shown that in wettability data, about 78% of the errors come from not effectively controlling cleanliness factors (Surface Science Reports, 2021).

This suggests that many experimental data could be influenced by "hidden contamination" or insufficient cleanliness detection, leading to significant deviations or misleading results. For example, one study showed that without proper water quality control, the measured contact angle could deviate by more than 20%. As surface science research deepens, this issue has gradually attracted attention in the academic world. This article aims to critically analyze the harm caused by neglecting cleanliness in contact angle measurement, emphasizing the necessity of strict cleanliness control in scientific experiments, and suggesting improvement methods.

I. Theoretical Framework: How Cleanliness Affects Measurement Accuracy

1.1 The Butterfly Effect of Surface Tension

Accurate measurement of contact angles relies on Young’s equation, which describes the wettability behavior of liquids on solid surfaces, as shown below:

cosθ=γLVγSV−γSL

Where γLV is the liquid-vapor interfacial tension, γSL is the solid-liquid interfacial tension, and γSV is the solid-vapor interfacial tension. The interaction between the liquid and solid at the interface and the shape of the droplet determine the contact angle. Therefore, the precise balance among these three factors determines the value of the contact angle. Contact angle measurement is not only an important tool for characterizing material surface wettability but also a key method in studying surface modification effects and the action of surfactants.

However, the presence of contaminants can alter this balance, particularly the trace contaminants in water. For instance, if the water contains 0.001% of dodecyl acid, the surface tension of the water can decrease from the standard 72.8 mN/m to 59 mN/m or even lower. This fluctuation in surface tension can cause significant errors in contact angle measurements, especially on hydrophilic surfaces (with contact angles around 30°), where the decrease in surface tension could cause a contact angle error of up to 8°, potentially misinterpreting a hydrophilic surface as superhydrophilic or falsely judging a surface modification experiment as a failure.

On the other hand, the impact of organic contaminants should not be underestimated. These contaminants often exist in very low concentrations in water but have a significant effect on surface tension. For example, certain organic contaminants can dramatically lower the surface tension of water, increasing the measurement error in contact angle tests, leading to misinterpretations of surface properties. In the design of superhydrophobic materials, contamination of the water can affect the wettability, potentially leading to project failure and wasted research resources.

1.2 Interfacial Effects of Contaminants

Contaminants not only exist in liquids but can also form thin organic layers on solid surfaces, significantly altering the surface energy of the solid. Surface energy is a critical factor in determining wettability—the lower the surface energy of a solid, the poorer its wettability (i.e., the larger the contact angle). For instance, a 0.5 nm thick layer of PDMS (polydimethylsiloxane) contamination can reduce the surface energy of a solid from 70 mJ/m² to 22 mJ/m². This change in surface energy directly leads to changes in the contact angle. A hydrophobic surface’s contact angle could decrease from a theoretical value of 110° to 98°, thus mistakenly interpreting the surface as less hydrophobic than it is, or incorrectly assessing the success of surface modification experiments.

The type and concentration of surface contaminants also have a significant impact on contact angle measurement accuracy. Different contaminants interact differently with the solid surface, making contact angle measurement more complex. In practical applications, many laboratories do not fully consider the impact of contaminants, leading to inaccurate experimental results. Therefore, only with strict cleanliness control can contact angle measurements truly reflect the intrinsic properties of surface materials.

II. Practical Criticism: Three Common Misconceptions

2.1 The "Visual Cleanliness Equals Standards" Fallacy

In experiments, many operators habitually rely on visual inspection to judge the purity of the liquid, assuming that water quality can be determined by its appearance. However, trace contaminants in water are often invisible to the naked eye, and these contaminants can severely affect the accuracy of contact angle measurements. For instance, water solutions containing 0.005% Tween 20 may visually appear identical to ultrapure water, but their surface tension drops from the standard 72.8 mN/m to 36 mN/m. Even slight amounts of surfactants can significantly reduce the surface tension of liquids, leading to accumulated contact angle errors. In some cases, measurement errors could exceed 200%.

To avoid this fallacy, laboratories should establish a more scientific water quality monitoring system rather than solely relying on visual inspection. Regular water quality testing and surface tension verification should become routine procedures to ensure the liquid purity meets experimental requirements.

2.2 The "One-Time Cleaning for Lifetime Effectiveness" Fallacy

Another common misconception is that materials cleaned once can remain clean for a long time. For example, many laboratories follow the RCA cleaning standard for silicon wafers, assuming that this will achieve a hydrophilic state. However, in reality, after being exposed to a cleanroom environment, materials can rapidly adsorb organic substances or other contaminants, leading to significant changes in the contact angle. Even in relatively clean environments, surfaces may still get contaminated over time, and this contamination is dynamic, influenced not only by external environmental factors but also by the chemical properties of the surface materials and the concentration of contaminants in the environment.

Therefore, the fallacy of "one-time cleaning for lifetime effectiveness" is untenable. Real-time cleaning and cleanliness monitoring before each experiment must become part of the experimental procedure to ensure that materials' surfaces are in an ideal clean state before each experiment.

2.3 The "Acceptable Error Range" Fallacy

Laboratories without strict cleanliness detection often believe that errors within a certain range are acceptable, even assuming that contact angle dispersion is normal to some extent. However, statistical analysis shows that in laboratories without cleanliness controls, the standard deviation of contact angle data can reach as high as 8%-12%, much higher than the 3% standard in well-regulated labs. This not only reduces the credibility of experimental results but also can lead to incorrect material performance evaluations, which in turn affects research directions and outcomes.

For example, in the development of hydrophobic coatings, even small changes in contact angle can directly affect the material performance evaluation, potentially determining the success or failure of the final product. Thus, laboratories must strictly control error margins to ensure the accuracy and reproducibility of contact angle measurements.

III. Detection Methods: Breaking Through Visual Judgments with Technological Solutions

3.1 Quantitative Detection of Liquid Purity

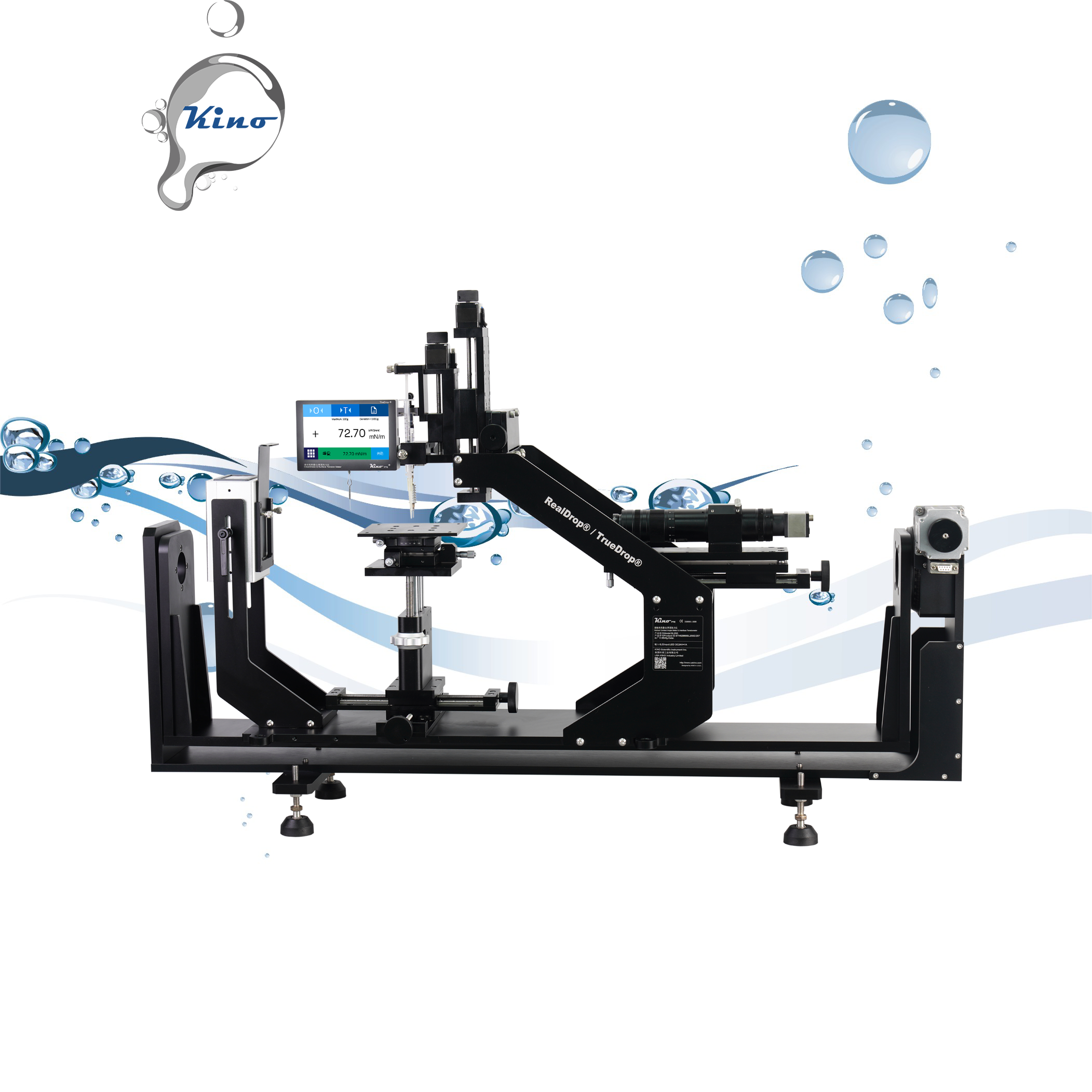

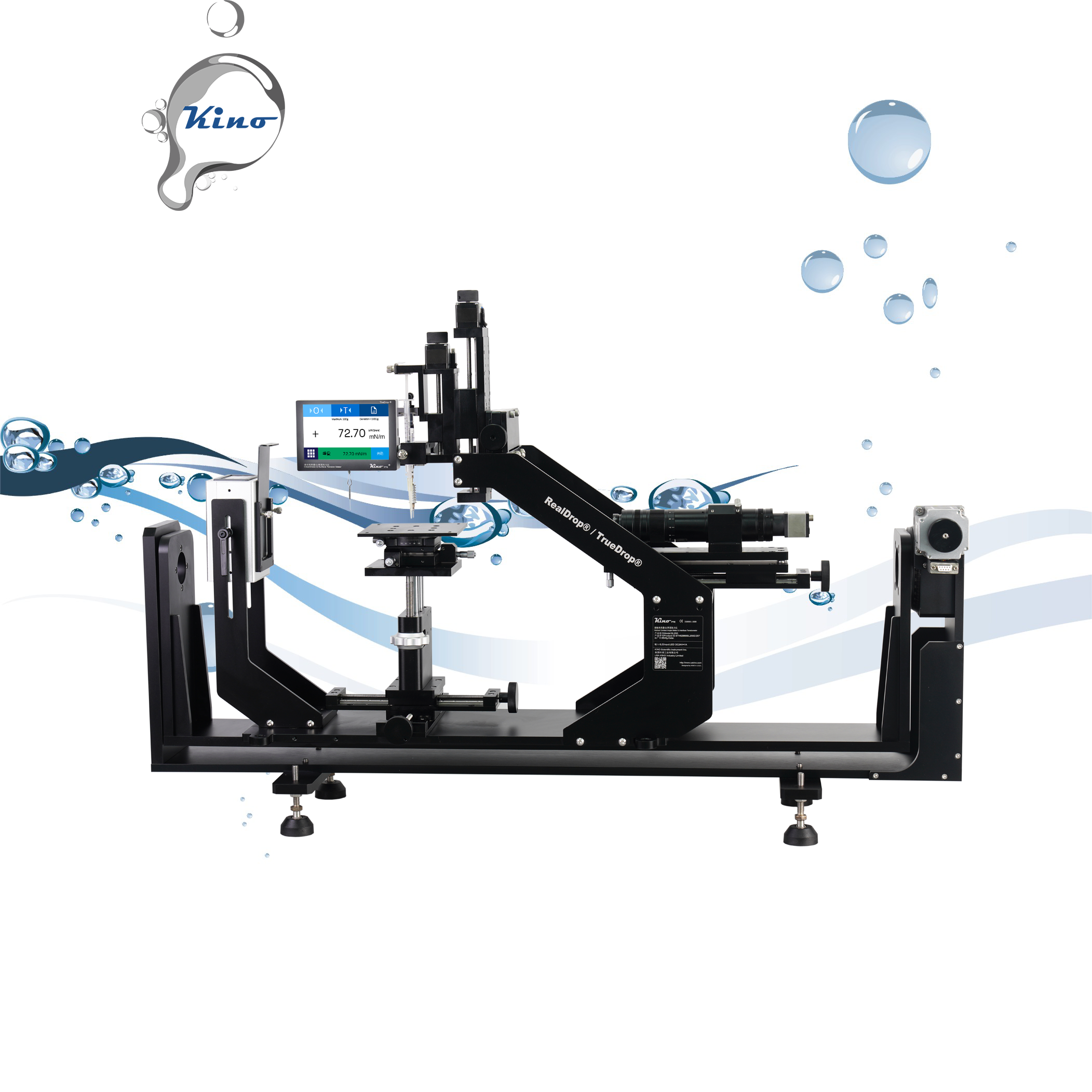

To effectively avoid the impact of water contamination on contact angle measurements, the pendant drop method is widely used for surface tension testing. By solving the Laplace equation:

ΔP=γ(R11+R21)

one can accurately detect the surface tension of liquids. When the surface tension of water drops below 70 mN/m, it indicates possible contamination. The surface tension of ultrapure water should be maintained around 72.8 mN/m, which not only complies with international standards but also minimizes the impact of contaminants on contact angle measurements. Therefore, regularly testing the surface tension of water, especially before each experiment, is a key step in ensuring the accuracy of contact angle measurements.

3.2 Dynamic Detection of Solid Cleanliness

In addition to the purity of liquids, the cleanliness of solid surfaces is equally important. The Wilhelmy plate method is widely used to detect the cleanliness of solid surfaces. By measuring the wettability force curve between the solid surface and the liquid, researchers can reveal changes in surface conditions. This method is highly efficient in detecting contamination layers as thin as 0.3 nm, ensuring that solid surfaces meet the experimental requirements. Furthermore, dynamic cleanliness monitoring during the experiment ensures that surfaces remain in an ideal clean state, which is critical for maintaining measurement precision.

IV. Case Studies: The Real Costs of Misjudgments

4.1 "False Hydrophobic" Misjudgment of Hydrophilic Materials

A photovoltaic company failed to control water quality during contact angle testing, leading to a measured contact angle of 5° and misjudging the failure of nanostructured silicon surface modification. After retesting with ultrapure water, the contact angle was corrected to 10°, thus preventing a $3 million equipment modification error. This case illustrates that neglecting cleanliness control can lead to significant economic losses and even impact technological innovation and product quality.

4.2 "Failed Hydrophobic Coating" Misjudgment

A ship coating project failed to detect contamination on the substrate during contact angle measurement, resulting in the false judgment of failed modification. After cleaning with xylene, the contact angle was corrected from 102° to 118°, a 13% deviation that almost led to the termination of the project, causing a loss of $10 million. This case again highlights the critical role of cleanliness detection in contact angle measurements, especially in high-value research projects.

V. Quality Control: Building a Four-Dimensional Defense Network

5.1 Double-Blind Testing for Medium Quality

To ensure the reliability of laboratory water quality, a strict double-blind testing system must be implemented. Water used in each batch of experiments must pass the following three standards:

-

Conductivity test: ≤0.1 μS/cm

-

TOC analysis: ≤5 ppb

-

Surface tension verification: ≥70 mN/m

These steps form the "triple protection" for experimental reliability, ensuring the liquid medium's purity and minimizing error sources.

5.2 Temporal and Spatial Monitoring of Solid Cleanliness

Before and after each experiment, real-time cleanliness monitoring of solid surfaces should be performed. A model for temporal cleanliness and contamination accumulation monitoring should be established to ensure that surfaces are always in an ideal clean state throughout the experiment. This measure is crucial in preventing surface contamination from interfering with contact angle measurements.

5.3 Data Credibility Evaluation Matrix

Introduce the Contact Angle Quality Index (CAQI), which quantifies the credibility of experimental data by combining liquid purity, solid surface cleanliness, and data dispersion. When CAQI ≥ 0.95, the data can be considered reliable. This standard provides laboratories with a clear framework for quality control.

VI. Philosophical Reflection: The Reconstruction of Measurement Ethics

Neglecting cleanliness detection is not only an oversight of measurement accuracy but also a departure from the scientific spirit. Scientific experiments should strictly adhere to ethical principles, which include a strong emphasis on experimental precision. Contact angle measurement, as an important experimental tool in surface science research, must include cleanliness control as an integral part. Every laboratory should ensure that the liquid and solid media meet the standards before each experiment and continuously monitor and correct the experimental environment to maintain the highest level of accuracy.

Conclusion: The Philosophical Dimension of Measurement Precision

Contact angle measurement is not just a tool for surface science research; it is a window into the fundamental properties of materials. In this process, cleanliness control plays a crucial role, and scientific experiments should not stop at operational norms but strive for data precision and reliability. In this ever-evolving field, strict cleanliness control not only improves the credibility of experimental results but also drives scientific research forward.